(Reported by Ren Weizhuo from Xi'an Heavy Equipment & Technology Co., Ltd.) Recently, the 1780mm hot rolling project of Indonesia's Guangqingde Metal Rolling Co., Ltd. (GCDMR) hot rolling plant, , undertaken by Xi'an Heavy Equipment & Technology Co., Ltd.(referred to as XHET),a wholly-owned subsidiary of Sino-heavymach, for the mechanical-electric-hydraulic general contracting completed the full-line hot test and successfully rolled the first coil. The equipment operated stably during the hot commissioning with excellent coil shape. The scope of the project contract includes the electromechanical-hydraulic design and complete sets of equipment supply, equipment commissioning, performance assessment and acceptance, as well as providingtechnical guidance and related training. This is the first set of modern hot rolling equipment for stainless steel and carbon steel exported overseas by Sino-heavymach,with comprehensive technical performance reaching the international leading level.

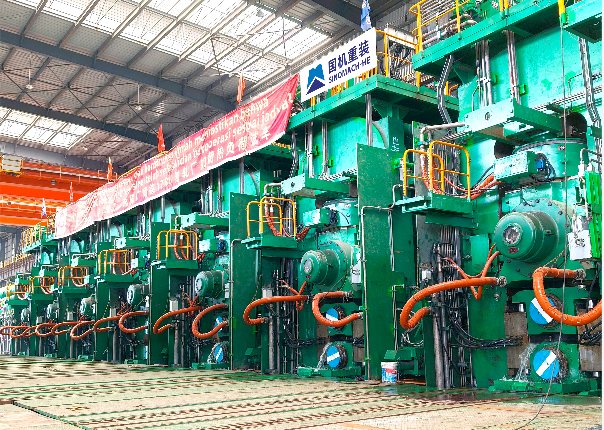

As a modern hot strip rolling production line, this project is jointly invested by Tsingshan Group and Delong Group in Tsingshan Industrial Park (IMIP), located in Morowali County, Sulawesi Province, Indonesia. The project has an annual production line of 4.5 million tons of 1780mm hot rolled strip steel, of which the annual output of stainless steel is 1 million tons and carbon steel is 3.5 million tons. Strong support received from SINOMACH-HE leads to successful implementation of this project. Under the corporate culture guidance of "Harmony and Benevolence" of SINOMACH-HE, Sino-heavymach meticulously organized, precisely designed, finely manufactured, and provided precise services. They fully leveraged their strong technological research and development capabilities and complete industrial chain for significant technical equipment manufacturing capabilities, combining advanced equipment such as mature and reliable roughing mill and finishing mill units with new-generation bending and shifting roller system, and hot coil box saturated purging system to create a high-quality and high-stability hot strip rolling production line which can meet the needs of a mixed production model for high-efficiency rolling with annual output of 4.5 million tons of various grades of carbon steel products and multiple series of high-quality stainless steel products, promoting the advancement of metallurgical equipment towards high-end, intelligent, and green development.

The 1780mm hot strip mill project is a significant overseas project successfully implemented by Sino-heavymach .It is also another major steel project undertaken by Sino-heavymach in Southeast Asia following several billet and slab continuous casting projects in Thailand, Philippines, and Indonesia. The successful hot test of this project fully demonstrates Sino-heavymach's technical capabilities in the field of hot strip rolling for strip steel and further embodies the commitment of "Serving the country with Technology, Equipping the world."

In the future, Sino-heavymach will take the commissioning of this project as an opportunity,and continue to closely follow the domestic and international development steps of Tsingshan and Delong Groups, and steadfastly participate in the high-quality construction of The Belt and The Road Initiative. Through low-carbon metallurgical technology and digital methods, it will contribute to helping overseas steel enterprises reduce carbon emissions, create greater value, and contribute the strengths of Sino-heavymach.