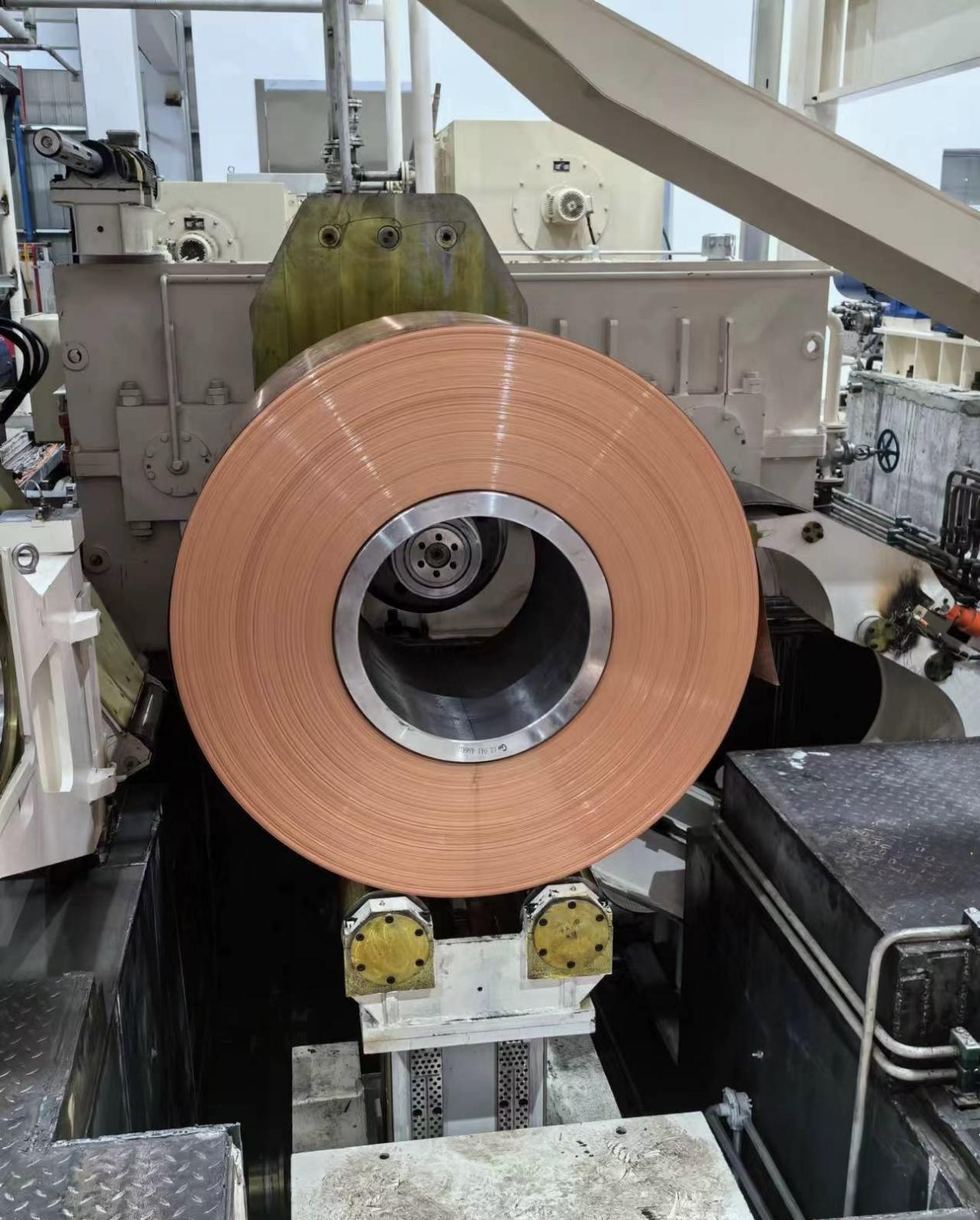

(Reported by Su Wenting from XHET and Qian Guangkuo from Department of Strip Rolling Technology) On January 31st 2024, the newly-built high-precision 800mm copper strip 6-hi reversible finishing mill in Ningbo Xinyue Alloy Material Co., Ltd. (Ningbo Xinyue for short) went through the hot test successfully on its first trail. This project was contracted by Xi’an Heavy Equipment & Technology Co., Ltd.(XHET for short), a wholly-owned subsidiary of Sino-heavymach and designed by Department of Strip Rolling Technology of Sino-heavymach for Xingye Shengtai Group Co., Ltd.(Xingye Shengtai Group for short).

Xingye Shengtai Group is a leading specialized copper alloy manufacturer in China, and has cooperated with foreign equipment manufacturers for many times. This 800mm 6-hi finishing mill is the first domestic equipment Xingye Shengtai Group built, so they kept higher expectations for the equipment with the tight construction schedule. This time, Sino-heavymach has won the acknowledgment and appraisal from Xingye Shengtai Group with its superior technology strength and excellent site service.

The mill mainly produces phosphor copper, brass, white copper, red copper, high copper alloy and other high precision and high value-added copper strip, and its product size is thickness of 0.08mm-2.0mm, width of 400mm-650mm, max. rolling speed of 600m/min, product thickness precision of 1.5μm, and plate shape no greater than 8I. The project is collaboratively researched and developed by Sino-heavymach and XHET, and adopted UCM 6-hi rolling mill small roll diameter suitable for copper strip rolling. Some key technologies, such as the work roll positive and negative bending non-blind zone switching, intermediate roll on-line shifting, parallel speed regulation coiler with wider tension range, high-efficiency servo control hydraulic drive system, high-precision flatness measuring and control system, high-efficient strip surface degreasing device, and high-quality product surface quality integrated control technology etc. were adopted to ensure the high-precision product,and high surface quality requirements. The automation control system applied gauge control model, level 2 model, and high-precision flatness control model, which were independently researched and developed by XHET. Based on these, the first high-precision coil was produced with the thickness of 0.29mm and thickness tolerance less than ±2um. Moreover, the rolling force is calculated accurately, and the mill starting thickness deviation is less than 10um, so the flatness control is excellent, and the produced coil could completely replace imported products.

In recent years, Sino-heavymach has continuously cultivated the high-precision copper strip mill market, mastered the core processes and key equipment, constantly participated the high-end market, and made persistent efforts to realize the localization of high-end rolling mill equipment. The put into operation of this project will further increase Xingye’share in high-end copper strip market, and consolidate Xingye's leading position in high-end copper-based alloy plate and strip market.