2. Wet dust removal electrostatic precipitator system (EPS )for steel strip hot rolling and hot scarfing machine

Introduction of products:

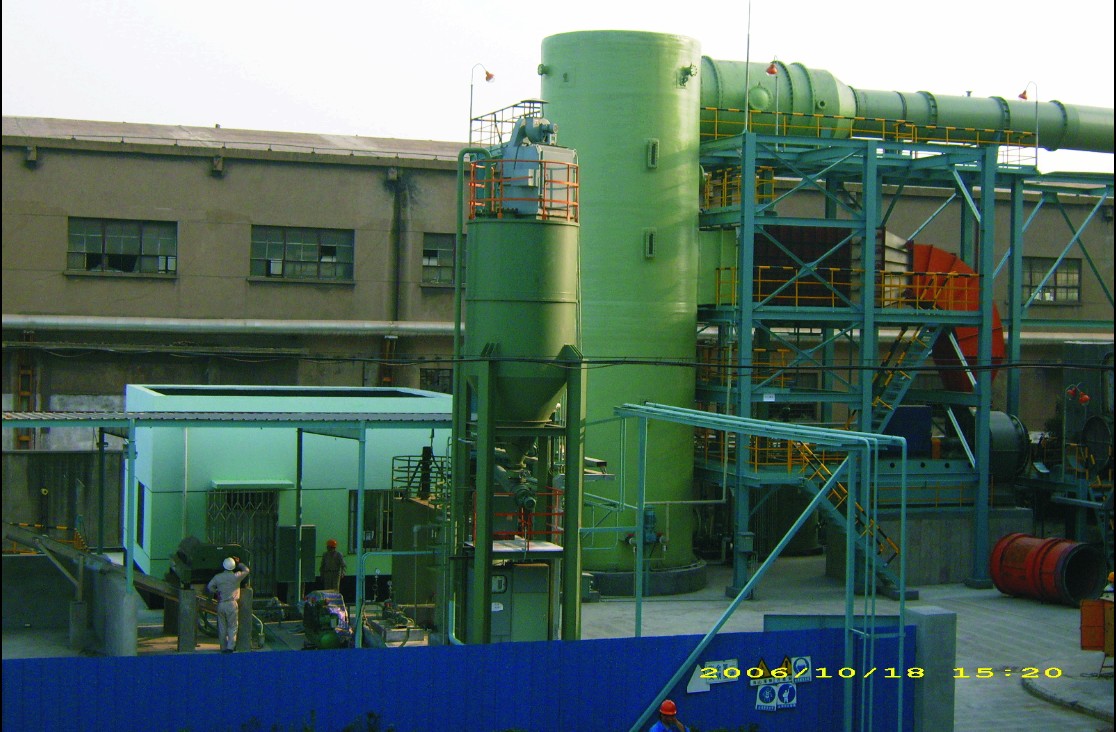

Flue dust of mechanical hot scarfing machine dedusting

Main parameters:

Treatment capacity for flue gas :60000-300000 m3/h

Temperature for flue gas:~ 80℃

Resistance loss:≤ 500Pa

Dust emission concentration: ≤ 20mg/Nm3(Dry,continuos testing)

3. Wet EPS for coal gas of blast furnace ,converter and producer furnace

Introduction of products:

Dust of gas shall be removed by wet EPS.

Main parameter: Dust emission concentration: ≤ 10mg/Nm3

4. Flue gas EPS for for boiler of power station

Introduction of products:

Dust of gas shall be removed by EPS of boiler of power station.

Main parameter: Dust emission concentration: ≤ 50mg/Nm3

5.EPS for flue gas of sintering machine

Introduction of products:

EPS of sintering machine head is used for removing the dust of flue gas.

Main parameters:

Area of sintering machine: 24~450m2

Dust emission concentration: ≤ 50mg/Nm3

6.Flue gas EPS for chemical and non-ferrous industries

Introduction of products:

Electrostatic precipitator for chemical and non-ferrous industries

Main parameters:

Section area of Electrostatic Precipitator: 10-260m2

Dust emission concentration: ≤ 50mg/Nm3

7. EPS for cement rotary kiln

Introduction of products:

EPS for cement rotary kiln is used for removing the dust into flue gas

Main parameters:

Dust emission concentration: ≤ 50mg/Nm3

8. Flue gas desulfurization、dedusting and denitration system forindustry kiln

Introduction of products:

On the premise of kiln pressure shall not be impacted, remove the SO2、NOx and dust when industry kiln started to produce.

Emission index:

1 SOx: 100mg/Nm3

Dust: 30mg/Nm3

NOx: 200mg/Nm3

9. Flue gas desulfurization for for boiler of power station

Introduction of products:

Flue gas desulfurization for for boiler of power station is used for removing the dust into flue gas.

Main parameters:

Capacity of the unit: 12.5-660MW

Emission concentration:100mg/Nm3

10. Flue gas desulfurization system for sintering machine head

Introduction of products:

Flue gas desulfurization system for sintering machine head is used for removing the dust when sintering machine head started to produce.

Main parameter:

Emission concentration of SO2:100mg/Nm3

11. Wet EPS for minuteness dust(PM2.5)

Introduction of products:

Apply to wet dedusting of minuteness particulate matter.

Main parameter:

PM2.5 Classification removal efficiency:≥80%

12. Flue gas dedusting system for EAF

Introduction of products:

Fine dust of EAF fume will be removed by bag-type duster

Main parameter:

EAF capacity: 3~180t

Dust emission concentration: ≤ 20mg/Nm3

13. Build and operational project (BOO,BOT) Urban sewage /wastewater treatment plant(WTP)

Introduction of products:

This type of BOT/BOO Projects are able to treat sewage /wastewater within jurisdiction of the Urban.

Main parameters:

Sewage treatment capacity: 10000~300000 m³/d;

Main process: multi-stage A/O;

Pollutant index:

Emissions limits of CODcr、NH3-N、TP conform to Environmental quality standards for surface water (GB3838-2002) ;Emissions limits of TN conform to the first class of a standard in Discharge standard of pollutands for municipal wastewater treatment plant.

MAIN PERFORMANCE

Pansteel Xichang Iron & Steel Co.,Ltd

Dry-type dust removing system of 3x210 T converter

Hebei Iron & Steel Group

Dry-type dust removing system of 1x150 T converter

Tangshan Donghai Iron & Steel Co.,Ltd

Dry-type dust removing system of 2x120 T converter

Tiantie hot rolling plate

Dry-type dust removing system of 2x190 T converter

TISCO

Dry-type dust removing system of 2x180 T converter

Baosteel

Dry-type dust removing system of 1x300 T converter