September 22,2025

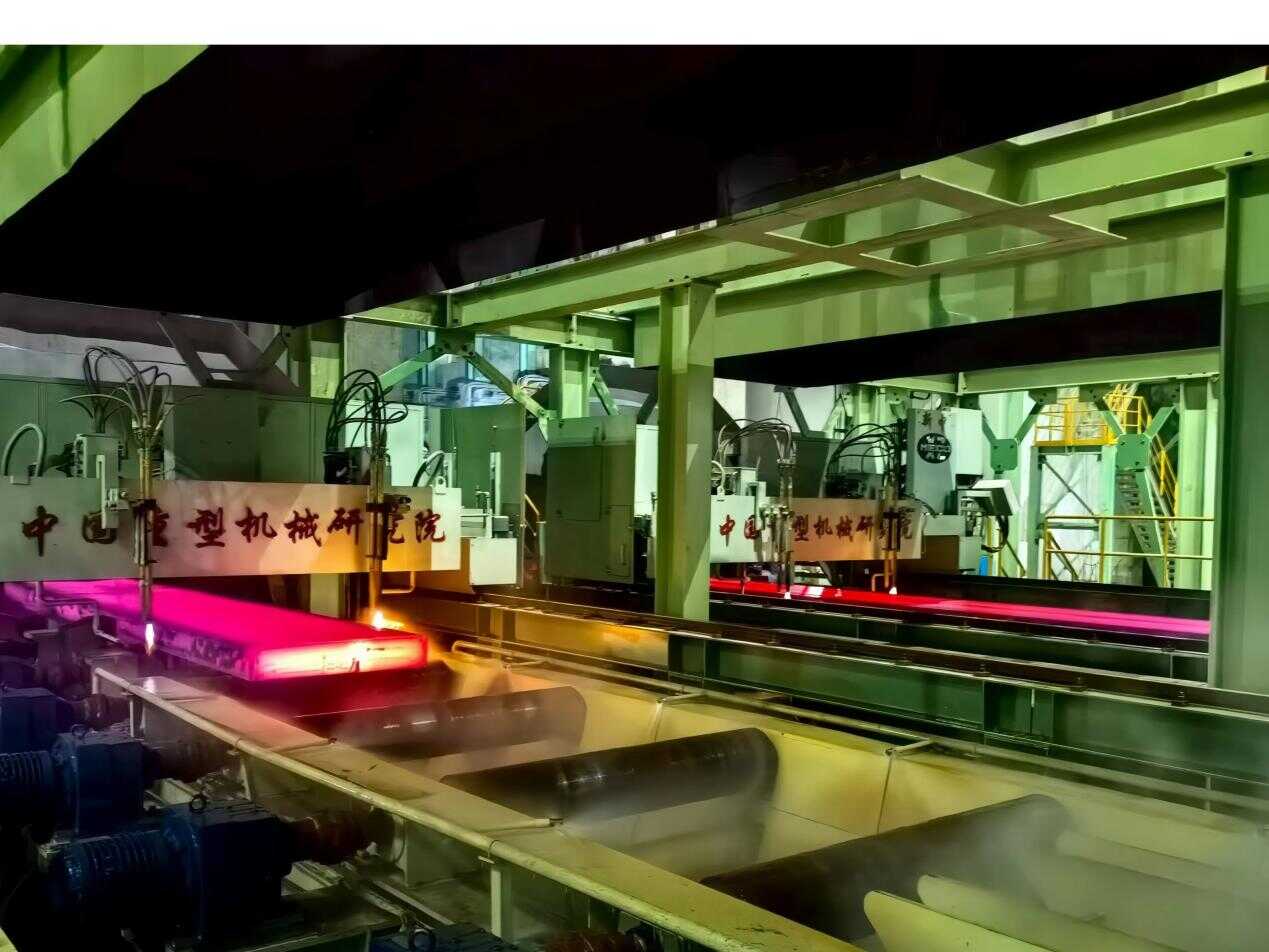

Recently, the two-machine two-strand 230×1350m² slab continuous casters contracted by China National Heavy Machinery Research Institute Co., Ltd. (Sino-heavymach for short) as EPC contractor for Guangdong Nanfang Donghai Iron & Steel Co., Ltd. (Guangdong Donghai for short) have succeed followed one after another. #2 Slab caster successfully achieved hot test on August 4, and #1 Caster on August 23 in succession. Both slab casters have demonstrated high efficiency, precision, and zero-fault operation, marking the grand success of this project.

These newly commissioned twin-strand slab casters are featured with the multi-grade compatibility, being capable of producing carbon structural steel, high-quality carbon structural steel, low-alloy structural steel, weathering steel, automotive structural steel, high-strength steel, pipeline steel, checkered steel plate, pressure vessels & boiler-grade steel, and various other high-end steels. The production line will significantly alleviate the shortage of premium steel products for advanced manufacturing in Southern China.

This project has integrated a series of industry-leading technologies, with its overall design aiming at high efficiency, premium quality, and advanced automation level. The slab caster is applied with a hydraulically-actuated ladle turret and tundish car, cooperated with the ladle and tundish weighing, real-time slag detection, and argon precise regulation to achieve whole process oxygen-free protected casting, tremendously improving the purity of liquid steel. The mould is equipped with the expert system and automatic liquid level control, with breakout prediction and constant-speed casting functions, significantly enhancing production stability and operational safety. The equipment is also adopted several advanced technologies such as the full-leaf-spring hydraulic oscillation, small-diameter densely arranged rollers, and continuous bending/straightening, effectively securing the quality of slab. In addition, the slab caster is leveraged some technologies like the mould online hot width adjustment, dynamic secondary cooling control, and dynamic soft reduction, enabling flexible adaptation to diverse steel grades, any specifications, and high-level casting requirements.

Behind the accomplishments lies the professionalism and hard work of the team members. During commissioning, Sino-heavymach's team worked around the clock tirelessly on the project site, optimized each operation meticulously, overcame the technical difficulties one by one, and served as a guarantee for the success of the trial run with the "zero-error" requirement. The collaborative construction team persevered through extreme heat and tight schedules to complete equipment lifting to position, accuracy alignment, and piping interconnections to exacting standards, laying a solid foundation for project progression.

The successful trial run not only demonstrates Sino-heavymach’s technological capabilities and brand leadership in the aspect of continuous casting engineering and equipment as EPC contractor, but also provides robust support for Guangdong Nanfang Donghai to optimize its product portfolio and enhance market competitiveness. Both parties affirmed that this collaboration has deeply strengthened mutual trust and accumulated invaluable experience for expanding cooperation into broader fields in the future.