September 22,2025

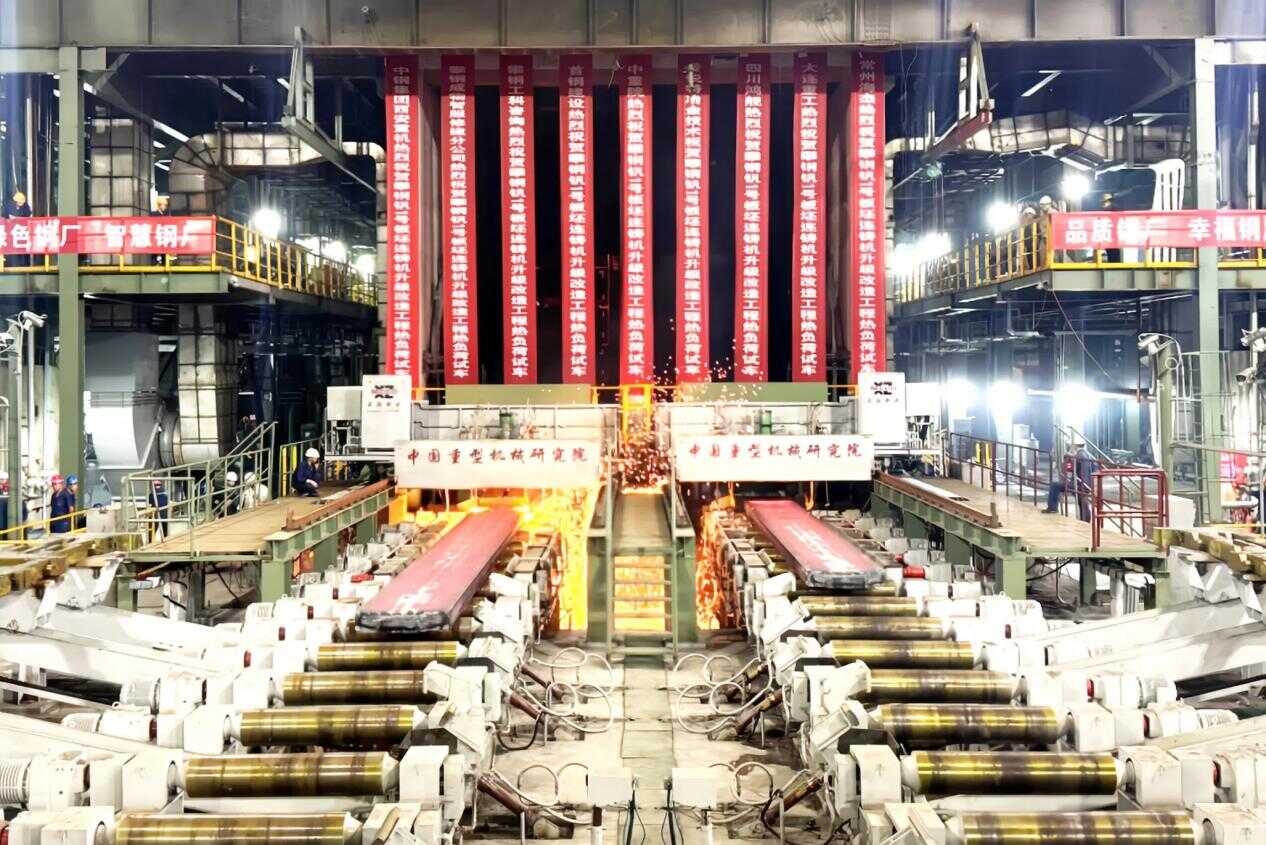

On August 31 2025, contracted by China National Heavy Machinery Research Institute Co., Ltd. (Sino-heavymach for short), the #1 slab continuous caster revamping project was passed through the hot test trial successfully. This project is a part of domestic complete-set and auxiliary utilities EPC project for the slab continuous casting system upgradation and revamping engineering project of Panzhihua Steel Vanadium Co., Ltd. (Pangang for short) Vanadium Extraction and Steel-making Plant. The completion of this revamping not only pushes China's metallurgical equipment capabilities but also provides the critical technical supports for building a domestic flagship production line specializing in first class home appliance and electrical steel.

Retrospected back to October 18 1993, China's first independently designed and manufactured million-ton-class continuous casting machine Pangang #1 slab caster has completed the hot test successfully, which was marked a historic breakthrough of ending foreign technology monopolies, establishing itself as a crucial milestone in the domestic development of China's metallurgical equipment. Over the past three decades, as the steel industry accelerated its transformation toward premiumization, intelligentization, and green manufacturing, the original continuous casting system was urgently required the upgradation and modernization. In January 2023, the successful hot run of Pangang's #2 slab caster has laid a solid foundation for this new round of technological reconstruction. Serving as the key role in China's major equipment and technology research & development, Sino-heavymach once again undertook the important mission of upgrading and revamping China first million-ton-class domestically-developed continuous casting machine.

In the spirit of Innovate Beyond Limits, Perfect Through Persistence, the project team successfully applied with several cutting-edge technologies including mould expert system, dynamic soft reduction, and dynamic secondary cooling, achieving intelligent transformation of Centralized control Centre and Unmanned Platforms. These innovations both honored original research & development aspirations and revitalized impetus to the traditional equipment.

It is notable to mention that, the project team brought together both senior engineers who have contributed to the original system's pioneering development, and the new generation of young technical experts. They are working in seamless collaboration, overcoming an extremely tight schedule, complex technical challenges, and immense workload pressures to complete the revamp activities in just 144 days, a full 9 days ahead of schedule, setting a new record among similar revamping projects.

When the hot liquid steel is casted into shape, the site engineers and construction team witnessed their dreams solidifying. From Creating existence from nothingness in the year of 1993 to Perfecting excellence from existence in the year of 2025, Sino-heavymach and Pangang have jointly propelled China's self-independently development of continuous casting technology over past 30 years.

Three decades of relentless endeavor, and three generations of striving in succession. The successful revamp of Pangang's #1 slab caster not only vividly demonstrates the advancement of China's metallurgical equipment technology, but also stands as an exemplary model of collaborative innovation and win-win cooperation among central enterprises. This enduring spirit of knowledge transmission will undoubtedly inspire more scientific and technological professionals to march steadfastly forward on the path of independent innovation.